15 kinds of stone surface processing technology you know?

For the study of materials, we all know that we should be from the material properties, common types, design drawings, node practices, use of skills, edging and sealing, process, quality problems, etc., for systematic learning plus the use of the project in order to more comprehensive mastery.

Take the stone, in addition to the above content also need to understand some of the material indicates that the treatment process, so that it can be better utilized in the project. Next, from the following 3 aspects to explain the surface of the stone process:

1. Why designers need to understand the surface treatment of stone?

2. Which stone can be surface treatment?

3. What are the common forms of stone surface treatment?

1. Project design issues demand

Many years ago, I asked the former designers around the stone in the interior decoration of the form of expression, they told me, “as a designer, we just need to remember that the stone is divided into matte, polished, grooved three common forms on it, the other forms of expression are special forms, basically in the space will not be used, there is no need to go to the study.”

So, naive me to believe, from that after many years never bothered to study the stone of more processing forms, until I encountered the following two design problems:

Problem 1:

What is the significance of stone surface treatment?

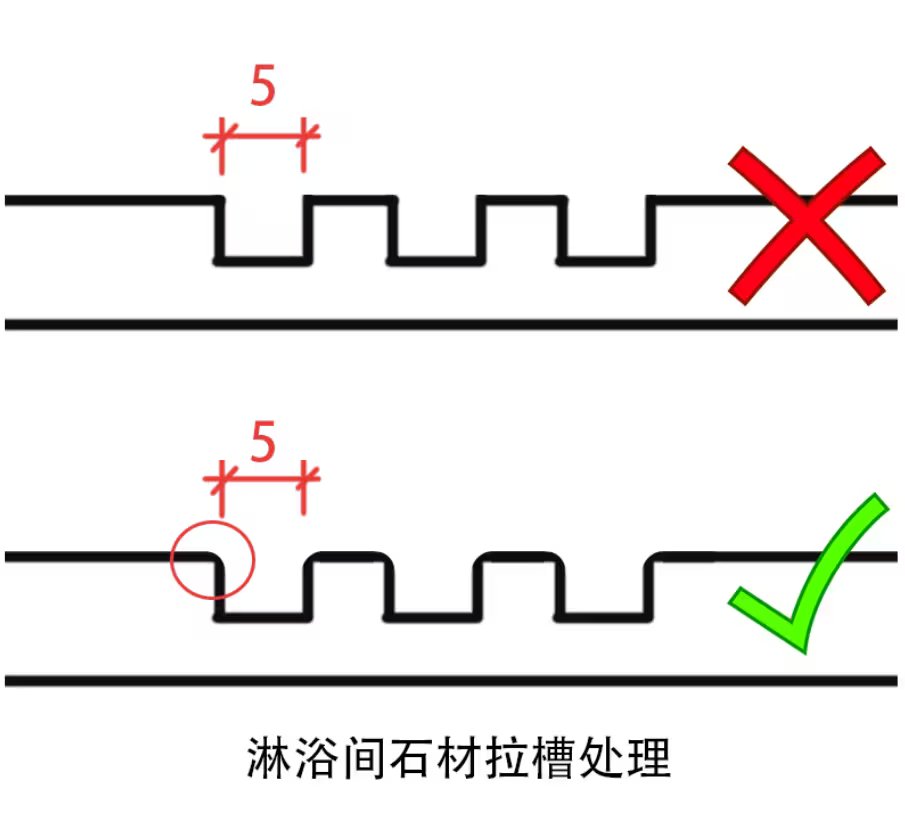

Designer in the bathroom area of a hotel, in accordance with the conventional form of stone anti-slip, made a 5 * 5mm grooved black gold stone, the result is that many guests in the use of the stone accidentally cut their toes, have complained.

This kind of thing is more common, but also the domestic designers in the use of grooved stone is the most likely to make mistakes.

There are 2 ways to optimize:

① Polishing the edge of the 5*5mm groove into rounded corners like the picture above.

② Change to other stone forms, such as acid-washed surface, natural surface.

Problem 2:

In the area of the elevator hall where people come and go, taking into account the retro mood of the design requirements, the designer used a rough lychee surface on the ground in the form of treatment, which resulted in hiding dirt, inconvenient cleaning, and after a long time, it was extremely unsightly.

2. the program itself on the demand for stone

A. to meet the safety of the stone itself

Because the stone is a natural material, if not for its surface treatment, after the factory is easy due to chemical reactions lead to alkali, yellowing and even weathering.

B. to meet the functionality

Different spaces, different design techniques, need different properties of the stone to meet its functionality. Such as the wet area of the bathroom can not be used glossy stone, the hotel lobby stone will not be used without glossy stone, service-oriented space needs to consider the durability of the stone and so on.

C. to meet the aesthetic

Any decorative materials, are in the space to give decorative, different stone surface treatment, can also meet different design concepts. Such as: want the effect of opulence, you need high-gloss stone; to create a return to the natural mood, irregular matte surface is the best choice, and so on.

What is the surface treatment of stone?

Various stone surface treatment form show

1. in order to ensure the safety of the stone itself, will be used on its surface with different treatment methods, so that it presents different material styles, in order to meet the needs of a variety of design, which is known as the stone surface treatment.

2. any natural stone, can be surface treatment, only according to the different types and patterns of stone, suitable for the surface treatment form is different, according to the degree of hardness and softness of the stone and the characteristics of the stone, choose the appropriate form of surface treatment, such as: black gold sand is suitable for axe surface or groove surface, while the rainforest brown is suitable for matte and polished treatment only.

3. according to the above mentioned three elements of the design can know, in order to ensure the safety of the stone, the final impact of the choice of stone is only functional and beautiful, all the stone surface treatment is also centered around these 2 points.

In other words, the owner spends money to buy done surface treatment of stone, either for better use, or for better look.

In addition, from the anti-slip, stain-resistant, easy to clean and anti-collision dimensions to make the stone better to use, but also extends the pickling, flaming, lychee surface, chamfered rounded corners and so on.

In addition to anti-slip and anti-collision, all the rest of the surface treatment, personal understanding is to meet the needs of the decorative design and the existence of, such as: antique surface, mushroom surface, bread surface and so on.

Common stone surface treatment

Most common surface treatment

1. Stone Polished Surface

Polished surface refers to the surface flat, with resin abrasives and other polishing on the surface, so that it has a mirror luster of the plate. General stone gloss can be done 80, 90 degrees, some stone species of gloss can even be done more than 100 degrees, but some stone species can not be polished, at most can only be made to matte. Generally speaking, the higher the gloss, the higher the price. Polished surface is generally used in flat curtain wall and indoor walls, flooring, etc., especially some high-grade buildings, its indoor walls and floors on the high requirements of light. Its special piece is high gloss, strong reflection of light, can fully display the stone itself rich and colorful colors and natural texture.

Suggestions for use:

① This treatment is suitable for almost any type of stone and is the most familiar way for designers to create a golden and grandiose effect.

② the use of this way of stone, pay attention to the relationship between the stone and the surrounding light, to avoid the leakage of light beads and light pollution.

2. Honed

Honed surface refers to the surface flat, with resin abrasives and other less abrasive treatment on the surface, so that the stone has a certain gloss and low gloss, generally in the 30-50, 60 degrees or so, but the reflection of the light is weaker, the surface is flat and smooth, the gloss is very low plate.

Recommendations for use:

① It is also one of the most common processing techniques, it is easy to create a natural and elegant spatial atmosphere, but also a lot of rock plate successive imitation of the surface treatment form.

② Apply to the need for a flat surface, without diffuse reflection, but does not produce a mirror effect, no light pollution in the space.

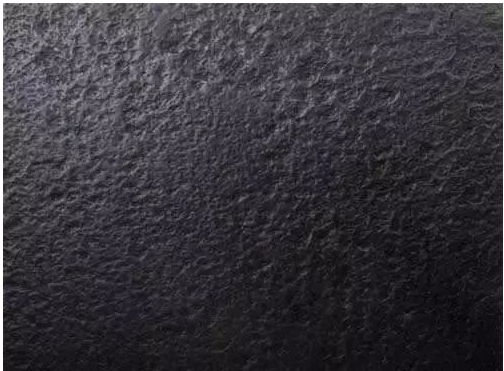

3. Flamed

Fired surface is to use acetylene, oxygen or propane, oxygen, or liquefied petroleum gas, oxygen as a fuel to produce high temperature flame on the surface of the stone processed into the rough surface finish. There are a small number of stone can not be processed with fire or said that the processing out of the effect is not good. As the effect of fire can burn off the surface of the stone some impurities and low melting point components, thus forming a rough finish on the surface, the hand will have a certain sense of sting. Fire surface processing of stone thickness has certain requirements to prevent the process of stone rupture, the general requirements of the thickness of at least 2CM, there are some stone thickness requirements will be higher. In addition, there are some materials in the fire process will have a certain discoloration, such as rust (G682), after the fire rust stone will show a certain reddish color, rather than the original yellow rust color. Flamed surface is characterized by rough natural surface, non-reflective, fast processing, relatively inexpensive, often used in dry hanging of external walls.

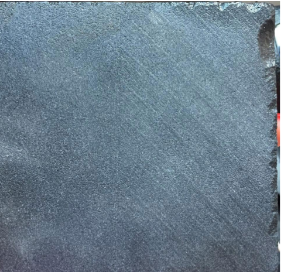

4. Bush-hammered

Bush-hammered surface, as the name suggests, the surface is rough, uneven, like lychee, there is an effect that imitates the water droplets dripping on the stone over the years.

Bush-hammered surface is shaped like lychee skin hammer on the surface of the stone, thus forming a rough surface on the surface of the stone in the shape of lychee skin, mostly seen on the surface of the carvings or the surface of the square stone and so on. Divided into machine Bush-hammered surface (machine) and hand Bush-hammered surface (handmade) two kinds, generally speaking, hand Bush-hammered surface than the machine Lai surface is more dense, but labor-intensive and time-consuming.

Suggestions for use:

Bush-hammered surface of the grainy sense of heaviness, suitable for decorative finishes, not easy to be used for frequent contact with water vapor and easy to hide dirt occasions, such as showers.

5. Chiseled

Chiseled surface with a word type hammer in the stone surface staggered knocking shape such as the appearance of the rough surface of the dragon's eyelid, is one of the most common way of surface treatment of granite carvings, and lychee surface, is divided into machine and handmade two kinds.

Suggestions for use:

This kind of stone surface texture is rich, suitable for showing personality or return to the natural space used.

6. Rough-picked / pineapple

Rough-picked surface (Pineapple surface) is the stone surface with chisel and hammer into the appearance of the appearance of pineapple skin plate. Pineapple surface than the lychee surface and longan surface particles more obvious. Sub-fine can also be divided into coarse pineapple surface and fine pineapple surface two kinds.

Suggestions for use: its material texture just the opposite of the water spray surface, weak sense of concave-convex, granularity, and concave-convex than the lychee surface is obvious, so the applicable space needs to be obvious stone particles when used.

7. Antique Face (Flamed+brush)

In order to eliminate the harshness of the surface of the flamed surface, after the stone is first flamed, then brush it with steel brush for 3-6 times, i.e. antique surface. The antique surface has the concave and convex feeling of flamed surface, and it is smooth to touch and will not be harsh, which is a very good surface treatment method. There are many other methods of antique surface, such as flaming after flushing, acid etching, direct steel brush or high-pressure water flushing surface and so on. The processing of antique surface is more time-consuming and expensive at the same time.

8. Mushroom

Mushroom surface is generally chiseled manually, the effect is similar to the natural split, but the surface of the stone is raised in the middle of the plateau-like profile around the depression, this stone is generally heavier. This processing method has certain requirements on the thickness of the stone, the general bottom thickness should be at least 3CM, the raised part can be 2CM and above according to the actual requirements. Mushroom stone is heavily utilized in economical fences.

Suggestions for use:

① This stone should be widely known, usually used as building enclosure, exterior walls and natural wind indoor space is widely used.

② When using this stone, attention should be paid to its specifications, thickness and process practices, if the stone used is too large or too heavy, not glued, easy to use dry hanging process.

9. Acid Washing (Pickling)

An acid-washed surface is a stone surface that is corroded with a strong acid, giving it small traces of corrosion and a more natural and rustic appearance than a matte finish. Most stones can be acid washed, but the most common are marble and limestone. Acid washing is also a way to soften the shine of granite.

Suggestions for use:

Acid wash surface stone is non-slip and stain resistant easy to clean, suitable for water, wet, often touching people's space, such as the shower room floor.

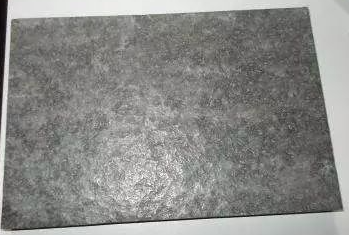

10. Natural Faced / Split Faced / Naturalcleft

The surface of naturalcleft is rough and raised, not as exaggerated as mushroom cleft, this surface treatment is usually cut by hand or burin in the mine to reveal the natural cleft surface of the stone, completely restoring the original appearance of the stone when it was mined, which is called “naturalcleft”. The natural surface is extremely rugged, and is used in a large number of products such as small cubes and curbstones.

Suggestions for use:

① As you can see from the picture, it is suitable for spaces that need to reflect the natural style, and is one of the most commonly used stone forms in the rugged style that has become so popular in recent years, and has been widely circulated in many Netflix cases.

② As with the mushroom surface, when using this stone, the weight, thickness, specifications and installation process should be considered.

11. Sawn Cut

Directly cut and shaped by the disc saw sand saw or bridge cutter and other equipment, the surface is rougher, with obvious machine-cut grain.

12. Grooved

In the stone surface to open a certain depth and width of groove stone grooved surface and brushed surface is a common and important technology in the field of stone processing. Through grooving and brushing, stone products get a unique texture and feel, making them more ornamental and decorative.

13. Sandblasted

Using ordinary sand or sand instead of high-pressure water to wash the surface of the stone, forming a flat sand effect of the decorative surface.

14. Water-jet surface (Water-jet)

Using high-pressure water to directly impact the surface of the stone, stripping the texture of the softer components to form a unique gross surface decorative effect.

Suggestions for use:

Its material texture bumpiness and granularity is weaker than pickled surface and lychee surface, but the texture is stronger than matte surface, so the application is the same as matte surface.

15. Brushed surface (Brushed)

Antiqued surface. The treatment process involves brushing the surface of the stone to mimic the natural wear effect of the stone.

There are also several stone surface processing methods combined, the formation of stone surface processing methods:

1. machine cut surface + steel brush 3 + plastic brush three, we usually called the leather surface, the English called Satin brushed or leather finish;

2. Litchi or fire iron + brush, generally brush one or two, three or more is the antique surface (antique)

3. water punch surface (water jet), the pressure of the water punch generally have 800kg and 1200kg

4. flamed + water jet flamed +water jet

5. sandblasted + water jet sandblasted + water jet

6. drawing surface (groove), groove generally do 3x3x3mm, 5x5x5mm, 10x10x5mm and so on

7. sawn cut +groove

8. polished +groove

9. flamed +groove

10. bushhammered+ groove

11. machine cut natural grooves, also called natural grooves or washboard grooves (natural grooves, sharp groove, machine pull)

Marble can be faceted in the following ways

A. sawn cut

B. polished

C. honed

D. antique orbrushed, note that marble antique interviews are acid washed with medicated water and not brushed with iron brushes

E. sandblasted sandblasted

F. lychee bushhammered

G. brushed surface groove stone study society (micro-signal stone5A)

H. machine cut after the natural surface (naturalgrooves, sharp groove, machine pull)

Note: the same kind of processing surface due to the different stone quality, different stone species to do the effect will be different.